Elite LAVAmaq 780 automatic cleaning and drying machine for tools and circular saws

From Inquire/month

Inquire

From just €300, access public grants that cover up to 45% of your investment in industrial machinery. Plus, receive a free consultation to review all available subsidies and financing options for your company, maximizing your savings.

From just €300, access public grants that cover up to 45% of your investment in industrial machinery. Plus, receive a free consultation to review all available subsidies and financing options for your company, maximizing your savings. We handle the entire process to ensure you secure the best public financing conditions. Eligible expenses include: acquisition of production machinery, modernization of industrial equipment, implementation of automated systems, and improvements in efficiency and safety. Offer subject to program availability and official acceptance.

From just 20 €/month (or 240 €/year), insure your machine against major risks, plus get a free consultation to review your company's insurance and find cost-saving opportunities.

Whether purchased from our website or elsewhere, we compare plans from top insurers — Allianz, Mapfre, Zurich, Reale, Axa, Helvetia, Generali, among others — to find your best option. Coverage includes: Fire, explosion, lightning strikes, and fire extinguishing costs. Theft and robbery. Ground collapse or landslides, flooding, wind, hail, and other similar natural events. Malicious acts by third parties. Impacts, overturning, falls, or collisions with mobile or fixed objects (excluding transport). Offer subject to acceptance by the insurance company.

From just 250 €, we arrange a fully independent inspection of your industrial machine before you finalize your purchase. A certified technician — with no connection to the supplier — will assess its condition and issue an impartial certificate, with results delivered online.

A qualified, independent technician will visit the machine's location to perform a comprehensive technical evaluation, confirming its operational readiness. The service is coordinated remotely, saving you time and travel. The inspection reflects the machine's condition at the time of assessment and does not include repairs, maintenance, or guarantees regarding future performance. Service availability may vary depending on the machine's location.

We offer a comprehensive logistics service specialized in industrial machinery. We handle the planning, coordination, and execution of the entire process, from collection at origin to delivery at destination. We have the necessary resources to handle, transport, and install heavy and large-scale machinery. We manage both national and international transfers, including customs procedures, special permits, and technical escorts when required. In addition, we provide temporary storage solutions, specialized packaging, and loading/unloading with state-of-the-art equipment, ensuring that each machine arrives in perfect condition and ready for commissioning.

COMPACT KNIFE-BLADES SHARPENING MACHINE WITH HIGH GRINDING CAPACITY UP TO 1230 MM LENGTH. AUTOMATIC MACHINE WITH COLOR TOUCH SCREEN AND PRODUCTION PROGRAM FOR EQUAL SERIES.

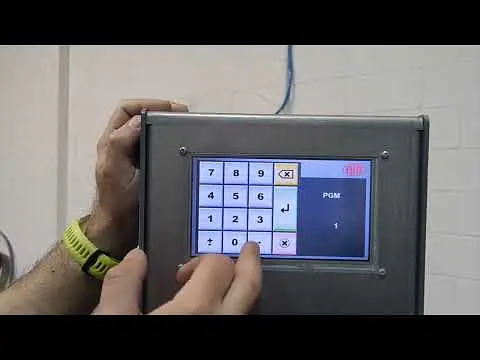

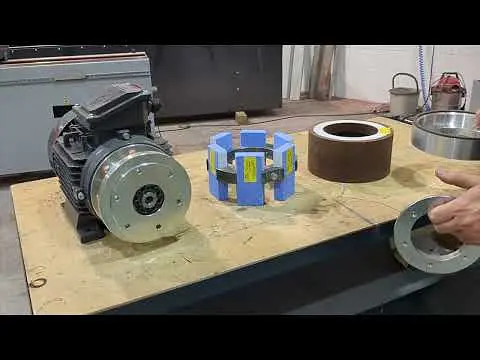

Features vibration-free carriage movement and a guiding system that absorbs vibrations generated during grinding. It has a high-power grinding wheel motor: 3 HP for 50Hz versions, 4 HP for 60Hz versions. The control panel includes automatic vertical movement of the grinding wheel and adjustable carriage travel. The work cycle is programmable via a color touch screen.

The ELITE model CU mini 1200 is the smallest series of sharpening machines for knife blades, capable of sharpening blades up to 1230 mm long with high removal rates. This fully automatic, simple, compact, and economical machine requires low maintenance. With its powerful grinding motor and vibration-free system, it achieves a good surface finish and efficient grinding times for its size. The work cycle of a sharpening workshop has been analyzed to optimize machine use, resulting in a control panel with a color touch screen and most of the programming from our largest blade sharpener: the ELITE model CU PRO.

Internally, it features a powerful control with 1 CNC axis, enabling an automatic and quality sharpening cycle. After the grinding cycle is completed, the fine finishing cycle can be activated to achieve the highest quality and minimal surface roughness of the sharpened tool. Occasionally, it can also sharpen large blades used in grinding mills.

The ELITE CU mini knife sharpener is suitable for a wide range of knives, including planer knives, wood chippers, and recycling knives. Its clean and sleek design ensures ease of use and maintenance. The control panel features a color touch screen designed with a fast and user-friendly interface, making it very easy to program the machine. It allows for the creation and saving of programs, perfect for knife sharpening workshops.

It permits the programming of the entire sharpening cycle like our larger machine models: Roughing process: total amount to grind, partial amount to grind per carriage pass, and carriage speed. Finishing process: total amount to finish, partial amount to grind per carriage pass, and carriage speed. Polishing: number of carriage travels and carriage speed. Grinding wheel down-feed: left, right, or both carriage travel sides.

The production program is designed for equal size knives. The carriage movement is facilitated by a powerful motor with a worm reducer. It includes a magnetic chuck for holding blades that can be magnetized and demagnetized via the control panel. The magnetic chuck is of the electro-permanent type, requiring energy only during magnetization or demagnetization, and it also has threaded holes for fixing other non-magnetizable supports or parts.

Equipping the CU mini with a FILTRAmaq SOLO filtration system reduces machine maintenance due to less wear on moving parts such as bearings and guides. Additionally, sharpening blades with coolant entirely free of contaminants and abrasive particles enhances the final finish and reduces roughness of the workpiece.

EQUIPMENT INCLUDES: 1230x100 mm magnetic clamping plate, maximum distance between plate and grinding wheel: 95 mm, adjustable plate from 0º to 90º, automatic grinding wheel lowering, partial lowering adjustable from 0.01 mm to 0.5 mm, and total lowering adjustable from 0 to 5 mm. Production program for sharpening blades of the same size, 3 HP grinding wheel motor (4 HP optional for 60 Hz version), user-friendly control panel with LCD touch screen, refrigeration unit with a capacity of 70 liters, prepared for connection to the centralized filtration system model FILTRAmaq SOLO/PRO, motorized carriage movement, carriage speed variator, working length adjustment, grinding wheel lowering displacement using guides with anti-vibration bearings, and a manual inclinometer.

TECHNICAL SPECIFICATIONS: USEFUL WORK CAPACITY up to 1230 mm, grinding wheel motor power 3 HP for 50 Hz version - 4 HP for 60 Hz version, grinding wheel diameter 150 mm, automatic and programmable grinding wheel down feed by means of guides with anti-friction vibration-dampening slide bearings and trapezoidal spindle, carriage speed from 1 to 15 m/min, maximum distance between the grinding wheel and chuck 95 mm, magnetic chuck standard with 1230 x 100 mm size, chuck rotation from 0º to +90º, control panel with LCD screen and program storage, coolant tank 90 liters, maximum connected power 4kW.

AVAILABLE VERSIONS: Model CU mini 1200. Size 2200 x 650 x 1500 mm. Weight 500 kilos.

TECHNICAL REQUIREMENTS: Connection voltage: 220/400V 3Ph 50/60Hz. Required connection power: 4 kW.

OPTIONAL ACCESSORIES: Magnetic chuck with fixed polarity for tungsten carbide inserts, bellows cover, mist extraction system, segment holder, independent coolant tank (50 l/min), filtering system FILTRAmaq SOLO, CU mini with bellows cover and mist extraction system, segment holder, assembly of different grinding wheels.

From Inquire/month

Inquire

From Inquire/month

Inquire

From Inquire/month

Inquire

From Inquire/month

Inquire

From Inquire/month

Inquire

From Inquire/month

Inquire

Whether you've found equipment on our platform or elsewhere, we can help you secure the best financing terms. Contact us to explore your options.

We store cookies to collect information about your interaction with our website. We use this information to personalize your browsing experience and to generate analytics and metrics about our visitors. By continuing to browse, you accept their use. To learn more, please see our cookie policy.