Elite LAVAmaq 780 automatic cleaning and drying machine for tools and circular saws

From Inquire/month

Inquire

From just €300, access public grants that cover up to 45% of your investment in industrial machinery. Plus, receive a free consultation to review all available subsidies and financing options for your company, maximizing your savings.

From just €300, access public grants that cover up to 45% of your investment in industrial machinery. Plus, receive a free consultation to review all available subsidies and financing options for your company, maximizing your savings. We handle the entire process to ensure you secure the best public financing conditions. Eligible expenses include: acquisition of production machinery, modernization of industrial equipment, implementation of automated systems, and improvements in efficiency and safety. Offer subject to program availability and official acceptance.

From just 20 €/month (or 240 €/year), insure your machine against major risks, plus get a free consultation to review your company's insurance and find cost-saving opportunities.

Whether purchased from our website or elsewhere, we compare plans from top insurers — Allianz, Mapfre, Zurich, Reale, Axa, Helvetia, Generali, among others — to find your best option. Coverage includes: Fire, explosion, lightning strikes, and fire extinguishing costs. Theft and robbery. Ground collapse or landslides, flooding, wind, hail, and other similar natural events. Malicious acts by third parties. Impacts, overturning, falls, or collisions with mobile or fixed objects (excluding transport). Offer subject to acceptance by the insurance company.

From just 250 €, we arrange a fully independent inspection of your industrial machine before you finalize your purchase. A certified technician — with no connection to the supplier — will assess its condition and issue an impartial certificate, with results delivered online.

A qualified, independent technician will visit the machine's location to perform a comprehensive technical evaluation, confirming its operational readiness. The service is coordinated remotely, saving you time and travel. The inspection reflects the machine's condition at the time of assessment and does not include repairs, maintenance, or guarantees regarding future performance. Service availability may vary depending on the machine's location.

We offer a comprehensive logistics service specialized in industrial machinery. We handle the planning, coordination, and execution of the entire process, from collection at origin to delivery at destination. We have the necessary resources to handle, transport, and install heavy and large-scale machinery. We manage both national and international transfers, including customs procedures, special permits, and technical escorts when required. In addition, we provide temporary storage solutions, specialized packaging, and loading/unloading with state-of-the-art equipment, ensuring that each machine arrives in perfect condition and ready for commissioning.

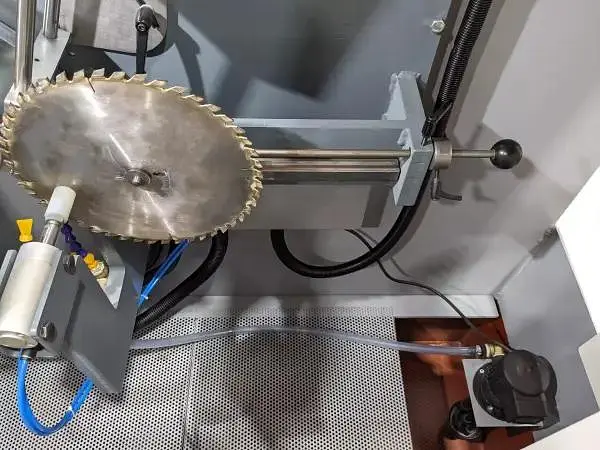

DOUBLE-WHEEL SHARPENING MACHINE FOR CARBIDE CIRCULAR SAWS

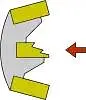

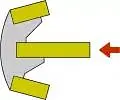

HIGHLIGHTS: Double grinding wheel system for sharpening the front and back in a single preparation. Double grinding wheel for face and top grinding in one setup.

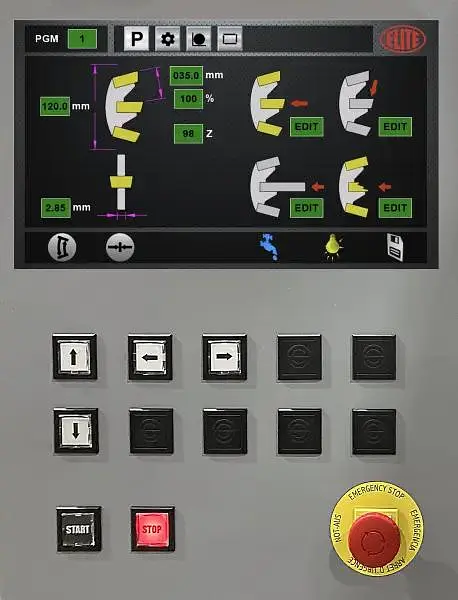

EASY TO USE: Control panel with 10" color screen featuring guided instructions. LOW MAINTENANCE: Hydraulic-free operation for trouble-free maintenance. 5 CNC axes for automatic work. Very compact machine with a wide range of disc diameters: from 100 to 850 mm.

ELITE AVB 850. THE CONCEPT. The ELITE model AVB 850 is our new and fastest sharpening machine for the top and face of all common tooth geometries in circular saw blades with carbide tips for blade diameters from ø100 to 850 mm. Total grinding time (face + top) is just 12 minutes and 33 seconds.

The double-grinding wheel system allows for complete sharpening of the face and back in a single setup: when the machine finishes sharpening the face, it automatically adjusts to sharpen the back, or when it finishes sharpening the back, it adjusts automatically to sharpen the face. Remove the finished saw from the machine!

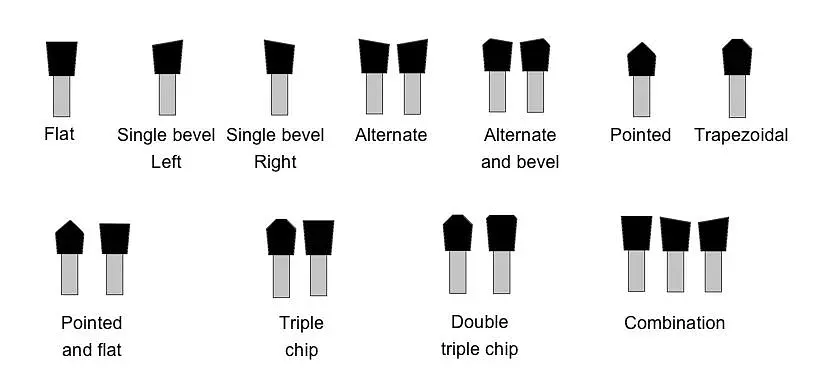

Face and top grinding in a single setup: ELITE AVB 850 model. One-pass external sharpening for tooth types: Flat, inclined, alternating, alternating with bevel, pointed, trapezoid, trapezoidal-flat, pointed-flat, alternating-flat, trapezoid-trapezoid.

With 5 CNC axes for complete machining of all common tooth geometries in one cycle, particularly short strokes ensure fast sharpening operation. Fully enclosed cabin for silent operation with a very fast door opening system that guarantees quick placement of the saw blade and access door for maintenance.

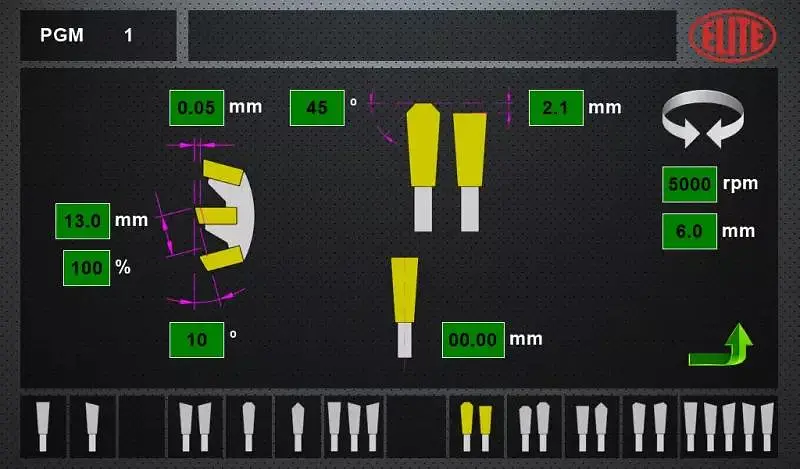

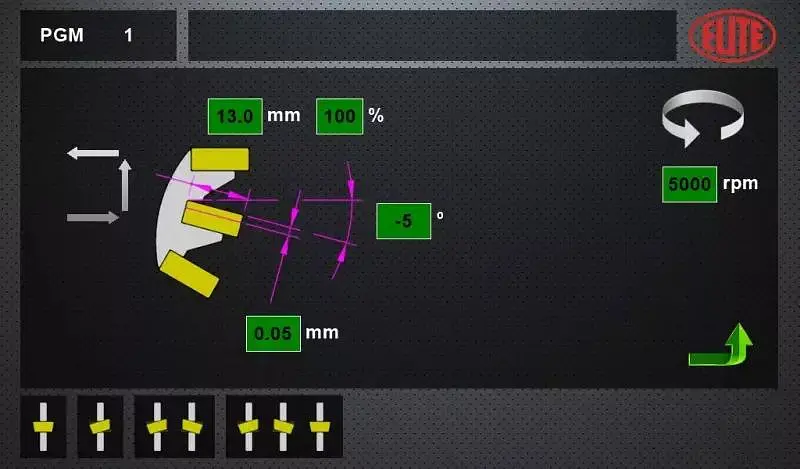

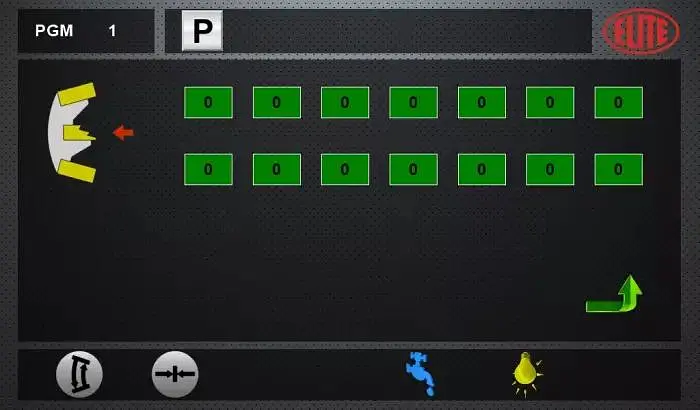

TOOTH TOP SHARPENING PROGRAMMING. The touchscreen enables quick and easy programming. The tooth shape can be selected at the bottom of the screen. The necessary data for tooth sharpening appears in the center of the screen when the tooth type is selected. The sharpening order can be chosen: first sharpen the back of the tooth, then the face; or in reverse order: first the face and then the back.

The machine will automatically sharpen the entire saw teeth (top + face) to achieve a completely finished saw.

TOOTH FACE SHARPENING PROGRAMMING. The face sharpening programming screen allows you to select, among other things, the type of grinding wheel sharpening: Start sharpening, move the wheel away, and exit without sharpening. Or start sharpening and exit polishing with the wheel.

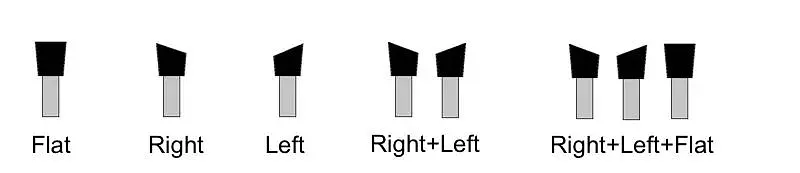

You can also select the direction of rotation of the grinding wheel: left, right, or reverse direction for each tooth. The speed of rotation of the grinding wheel can also be selected. Allowed tooth shapes vary: flat tooth, side angle, angle on both sides, or combinations. You can choose the sharpening order: first sharpen the back of the tooth and then the face; or in reverse order: first the face and then the back.

The machine will automatically sharpen the entire saw teeth (top + face) to achieve a completely finished saw.

GRINDING THE SHEAR ANGLE. STANDARD TOOTH FACE SHAPES.

BROKEN TEETH OR NEW TEETH. You can easily add and edit broken teeth or new teeth. This feature can then be activated or deactivated without having to change the entered values. Very useful, for example, for skipping broken teeth when sharpening the face but deactivating this option when sharpening the back.

VARIABLE PITCH: Precision and flexibility for complex geometries. The Tooth Pitch mode on the ELITE AVB 850 allows for highly precise programming and adjustment of the distance between teeth, accommodating a wide range of pitches including variable pitch and special tooth configurations. This system ensures perfect synchronization between the saw blade’s feed motion and the grinding cycle, delivering consistent sharpening quality regardless of tooth design.

With its intuitive interface, the operator can manually enter the desired pitch or select from pre-set parameters. The machine automatically detects each tooth position and adjusts the feed smoothly and accurately, reducing setup times and eliminating indexing errors. This mode is especially valuable for saws with complex geometries or mixed production runs that require frequent pitch changes. Its precision improves tool life and significantly reduces grinding wheel wear.

ELITE AVB 850. HOW IT WORKS. Automatic operation using 5 CNC axes: A: Tooth pitch. B: Tooth cutting angle. C: Lateral angle of the top of the tooth. X: Sharpening load. Z: Sharpening path. Easy-to-use control panel.

The color touch screen control panel allows for creating or editing a program while the machine operates on another program. Among the programmable values are: • Tooth angle programming. The wheel axis is automatically positioned to the value entered in the program. • Tooth geometry. • Sharpening path. • Sharpening load. • Sharpening speed. • Tooth pitch. • Tooth advance claw feed rate. • Number of teeth. • Broken teeth.

Up to 10 teeth/minute when grinding discs with flat trapezoid teeth. Up to 10 teeth/minute for the most typical tooth geometry: flat trapezoid. All movements have been optimized to reduce downtime, making the AVB 850 our fastest grinder, allowing a 96-tooth flat trapezoid disc to be ground in less than 10 minutes.

Variable wheel rotation speed from 2,500 to 5,000 RPM. Includes a variable frequency drive as a standard feature, allowing you to adjust the wheel speed to the optimal value required and reduce energy consumption.

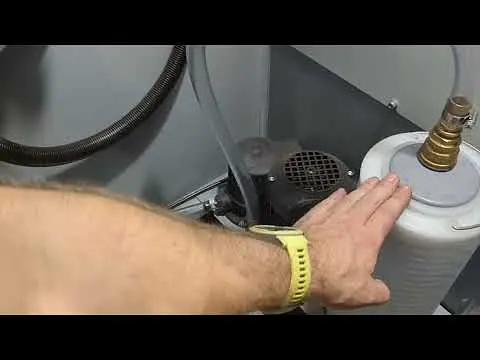

Integrated cooling system. The machine operates with water-soluble coolant or grinding oil for better sharpening quality and longer grinding wheel life. Integrated coolant system with 220-liter tank and removable grates for easy cleaning.

Easy access and maintenance. At the back of the machine, the electrical panel is found at the bottom, and the mechanical system is at the top, both protected by their corresponding easy-access panel, which also reduces the total space needed for the machine.

ELITE AVB 850. EQUIPMENT INCLUDED. Double wheel holder for sharpening the front and back surfaces. 3 mm feed dog. Device for serial sharpening of equal diameters. LED lighting of the work area. Ready for connection to an ELITE FILTRAmaq individual filtration system or a centralized filtration system.

ELITE AVG 850. SPECIFICATIONS.

AVB 850. Technical Data: Outside diameter of saw blade. From ø100 to ø850 mm. (4" to 33.5"). Bore diameter of saw blade. From ø10 mm. (0.34"). Thickness of saw blade. Up to 8 mm. (0.31"). Tooth pitch. Up to 120 mm. (4.72"). CNC controlled.

TOP GRINDING. Clearance angle. From +5º to +35º. Bevel angle. From -45º to +45º. Grinding path. Up to 25 mm. Available tooth shapes: Flat (P) - Single bevel (L/H or R/H) - Alternate (AT) - Alternate bevel (HGB) - Pointed tooth (PTR) - Triple chip (TRZ) - Pointed and flat - Triple chip and flat (TCH) - Double triple chip (D/T/C) - Combination (SLR).

FACE GRINDING. Hook angle. From -10º to +35º. Grinding path. Up to 25 mm. (0.98"). Available tooth shapes: Flat - Single bevel (L or R).

OTHER DATA. Grinding wheel motor: 1.5 HP. Grinding wheel speed: Adjustable from 2500 to 5000 RPM. Grinding wheel diameter for top: ø125 mm. Grinding wheel diameter for face: ø175 mm. 5 CNC axes: A: Tooth pitch - B: Tooth cutting angle - C: Lateral angle of the tooth back - X: Sharpening load - Z: Sharpening path.

Machine dimensions: 1650 x 1200 x 1900 mm. Machine weight: 690 kg.

TECHNICAL REQUIREMENTS. Precise 6 bar air connection. Connection voltage: 220/400V 2Ph 50/60Hz. Required connection power: 1.5 kW.

RECOMMENDED OPTIONAL ACCESSORIES. Saw holders for incisors and discs, and centering rings in various sizes. For better sharpening quality, it is recommended to equip the machine with the filtration system ELITE FILTRAmaq UNO. Filtration down to 2 µm.

DOWNLOAD BROCHURE. REQUEST INFORMATION. MACHINES COMPARISONS AT A GLANCE.

MODEL TOP GRINDING FACE GRINDING BACK OFF GRINDING SIDES GRINDING. AVB 850. All tooth shapes. All tooth shapes. No. No. AVB 750. All tooth shapes. All tooth shapes. No. No. SVG 850. All tooth shapes. Flat teeth. No. No. SVG 750. All tooth shapes. Flat teeth. No. No. MVB 850. Flat teeth. Flat teeth. Yes. No. MVB 750. No. No. Yes. No. MVB 670. Chipbreaker slots. No. No. No. MVB 650. No. Hollow face. No. No. GBT 851. No. No. No. Yes, both sides at the same time. GBT 850. No. No. No. Yes, both sides at the same time. GBT 750. No. No. No. Yes: One side at a time.

From Inquire/month

Inquire

From Inquire/month

Inquire

From Inquire/month

Inquire

From Inquire/month

Inquire

From Inquire/month

Inquire

From Inquire/month

Inquire

Whether you've found equipment on our platform or elsewhere, we can help you secure the best financing terms. Contact us to explore your options.

We store cookies to collect information about your interaction with our website. We use this information to personalize your browsing experience and to generate analytics and metrics about our visitors. By continuing to browse, you accept their use. To learn more, please see our cookie policy.